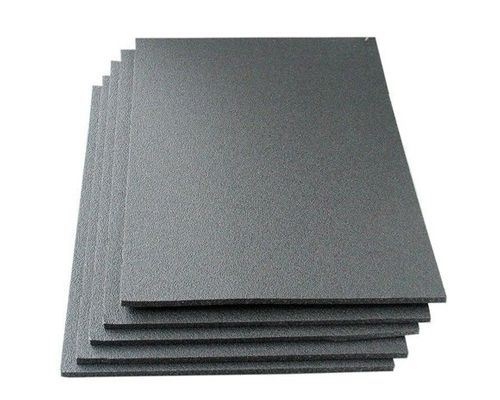

Cross linked polyethylene foam

XLPE is an acronym for cross linked polyethylene. XLPE is a thermosetting polymer meaning that the material (polyethylene (PE)) is cured under heat and in that process forms bonds in all directions forming a three dimensional matrix.

Cross-linked polyethylene foam (XLPE) is an ultra-durable closed-cell material that offers excellent chemical properties, thermal insulation properties, strong impact damping, and a host of other desirable attributes.

The difference between XLPE foam and EPE foam

EPE is inert and does not off-gas or produce an odor, whereas XLPE that is chemically cross linked (i.e. manufactured with peroxide) may off-gas or leave an odor affecting the presentation or even damage your product or equipment. Off-gassing may potentially damage optics or other sensitive equipment.

In a batch type operation, the polyethylene is mixed with organic peroxide such as dicumylperoxide and a blowing or foaming agent. The resulting mixture is then molded (i.e., compressed) into slabs and cross-linked by heating, under pressure, at an elevated temperature (e.g., from 135° to 205° C.)

We, “Quality Thermopack And Insulations Industries, are a renowned manufacturer of a comprehensive assortment of PUF Packaging Material, Formulated & Blended Polyol, Pipe Section, Thermocol Packaging Material etc.

Benefits of XLPE Foam Insulation

- Condensation proof

- High density

- Low thermal conductivity

- Aluminium foil Laminated high durability

- Self-adhesive to metal or any other surface

- Fire retardant & high temperature resistant.

Pipe Insulation | Low Price | Long Life belongs Maruthi Engineering solutions

XLPE Foam Insulation is made of Chemical cross-linked polyethylene foam. It is manufactured by high-temperature foaming after extrusion, cross-linked and foaming at the same time. It is the ideal foam for applications where support and high durability is required. XLPE foam is a strong, resilient closed-cell foam. XPE is most suitable for products requiring a shock absorbing, vibration dampening, insulation, barrier or buoyancy component etc.

We manufacture and supplying good quality XLPE foam insulation system for pipe, Duct, HVAC thermal insulation, roof, wall, outdoor home. Low-density polyethylene foam has numerous applications because of its many desirable properties including water-resistance, chemical resistance, energy-absorbance, buoyancy and cushioning characteristics.

Compressive strength is greater in denser foams, decreasing as density decreases. Low-density foams tend to exhibit more compressive creep, meaning they become less thick over time, than higher-density foams.